Calculating the number of sustainable bending cycles even the inventor of the wire rope oberbergrat albert from clausthal zellerfeld carried out fatigue tests with wire ropes to compare the service lives of different rope designs.

Wire rope design calculations pdf.

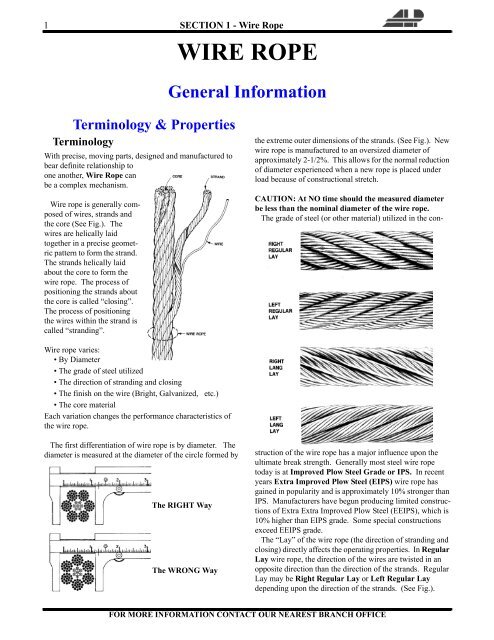

Wire rope slings wire rope environmental considerations wire core wire rope iwrc must not be used at temperatures above 400 f.

Calculation and to demonstrate the potential and limitations of the forecasting procedure.

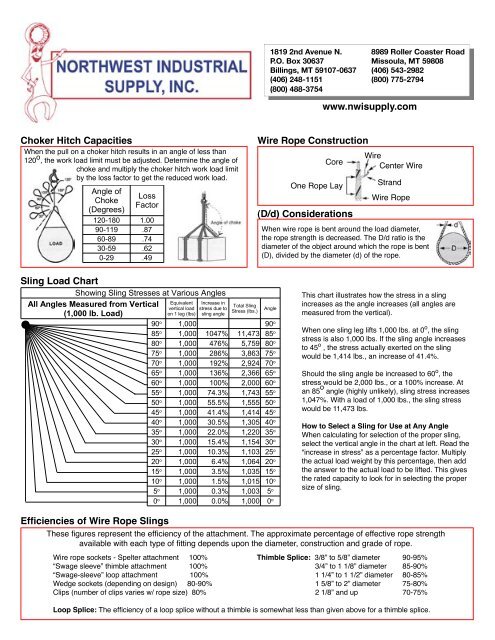

9 1 design load load to be lifted x assumed fos step3.

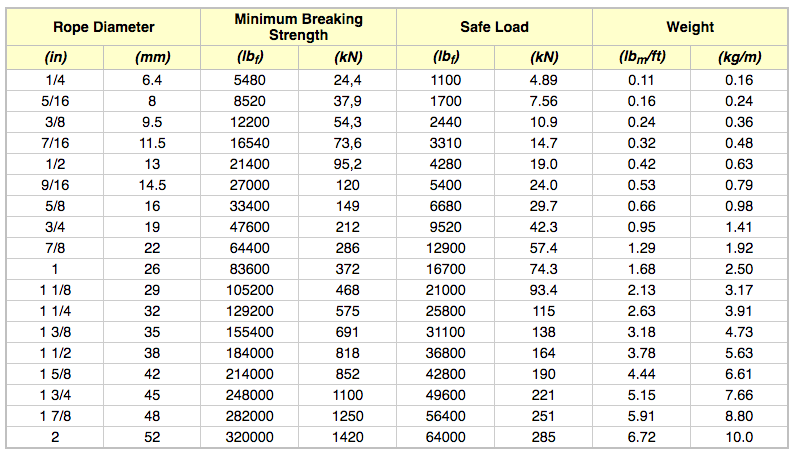

Selection of wire rope diameter d.

Many rope makers run their own tests on bending fatigue machines to determine those parameters for their own products.

Design results nomenclature results of 1st calculation if required results for iteration rope drive efficiency η s rope tensile force f s kn rope speed v s m min required usable winding capacity l w m load spectrum l i operating class t i mechanism group m rope diameter d mm gearbox size peg drum diameter d t mm.

Fiber core wire rope fc must not be used at tem peratures above 180 f.

The minimum design standards for a wire rope.

We apply thorough design and manufacturing controls including complete material trace ability.

Wire rope slings and wire rope assemblies.

Calculation of design load.

We take an active role in industry associations that develop wire rope specifications and standards such as astm a1023.

Calculate the design load by assuming a larger factor of safety say 15 or find the design load by assuming a factor of safety 2 to 2 5 times the fos given in ddb pg no.

Fiber core ropes should not be subjected to degreas ing solvents.